“Yeah, you will [make a mistake again]. But not 'cause you're you. Just 'cause [stuff] happens.”

– Carmy, “The Bear”

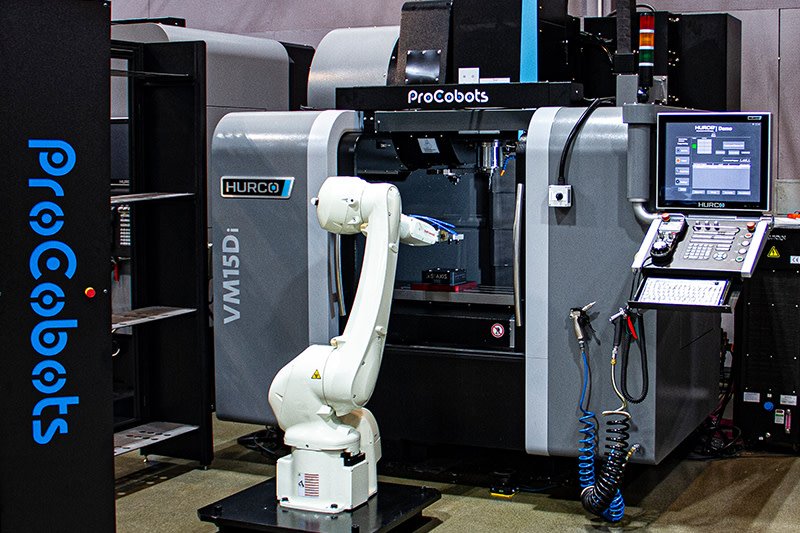

1. Hurco + Kawasaki Robotics

Dude, we’re weeks away from the greatest manufacturing trade show in the world! Here’s a sneak peek at some new metal: Hurco and Kawasaki Robotics announced a strategic collaboration to deliver turnkey industrial-grade robotic CNC machine solutions. They’ll combine Hurco’s CNC expertise with Kawasaki’s robotics to create no-code, easy-to-integrate automation systems. The future of manufacturing technology acquisition is not in individual machines but fully integrated cells of machines ready to rock out of the box.

2. Google's Ping Pong Robot

Google trained a table-tennis-playing robot to compete against humans, achieving notable success in terms of speed and dexterity, though it isn't Olympic-level yet. The bot won 45% of its matches against beginner to intermediate players but lost to advanced players. So, I know Google Cloud will indeed be at IMTS. I can’t say if they’re bringing their ping pong robot, but I can say that if they do, there are some AMT staffers ready to put it in its place!

.

3. CNC Giveaway

While this is nothing new, it has improved! At IMTS 2022, there was a raffle to win a brand new (maybe it was restored, but it looked like new) Bridgeport knee mill. I took a picture with it that you can see if you go almost two years back . And while there’s no replacement for a trued-up manual machine, Kennametal will offer attendees at IMTS 2024 the chance to win an SVM 4100 vertical machining center that’s fully equipped with Kennametal tooling.

4. Slow Is Smooth; Smooth Is Fast

Press brake operators in the United States often lack proper training, leading to safety risks and equipment damage. With the retirement of experienced workers, many new operators struggle with basic tasks like using protractors and understanding machine capabilities. Jim Blount emphasizes the importance of realistic training to ensure operators can safely and efficiently work with press brakes, advocating for a slow, steady learning approach to build confidence and competence.

.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at