Did you ever wonder what happens to an exhibit after the trade show ends? Rather than collecting dust in a storage room, some live on—a shining example is the Intelligent Flexible Manufacturing Cell from the AMT Emerging ��������ֱ�� Center (ETC).

As featured at IMTS 2018, the cell demonstrated how the communication protocol enabled components in an automated manufacturing cell to coordinate activities, share data, and demonstrate best practices for smart manufacturing. Today, the cell is the centerpiece of a $250,000 cooperative agreement between the U.S. Department of Commerce’s National Institute of Standards and ��������ֱ�� (NIST), and the Commonwealth Center for Advanced Manufacturing ().

“We are using the to demonstrate distributed manufacturing principles,” says Tim Bakker, PhD, CCAM Intelligent Factory Research Manager. “We can show OEMs and their suppliers how to build qualified parts by leveraging open standards and the digital thread.”

CCAM (pronounced “see-KAM”) is an applied research center and not-for-profit 501c3 with membership from industry, academia, and government. Its structure creates a research consortium to save members valuable resources by accessing pooled talent, tools, and technology to improve methodologies and increase product introductions (learn more in this on the IMTS Network).

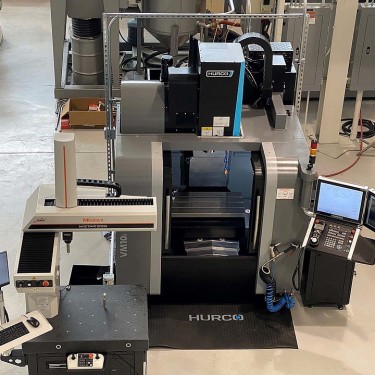

Digital Thread Key components in the Intelligent Flexible Manufacturing Cell are a Hurco VM10i machining center, a Mitutoyo MiSTAR 555 shop floor CMM, and a Universal Robot UR5 collaborative robot arm to move parts between the CNC and CMM. Cisco provides industrial hardware and an edge computing module. In addition to the physical components, three open standards play a critical role, specifically:

MTConnect enables machine-to-machine communication.

The STEP AP 242 managed model-based 3D engineering standard captures geometric design and tolerance (GD&T) data.

The Quality Information Framework (QIF) conveys metrology data.

“Using open standards lowers the entry barrier and cost of deployment, especially for smaller companies,” says Bakker. “Open standards allow for the creation of a robust, extensible digital backbone for the modern factory.”

“The Intelligent Flexible Manufacturing Cell encourages the manufacturing community to adopt a model-based engineering (MBE) approach,” adds Russ Waddell, Managing Director, MTConnect Institute, AMT. “When a company wants to buy equipment, they always ask, ‘Well, who else is using it?’ That’s easy for a machine, but more challenging for open standards and MBE. The Intelligent Flexible Manufacturing Cell will provide industry with encouraging IoT use cases.”

Knowledge Transfer The work being done by CCAM is essential for helping U.S. industry re-think and rebuild its chains. By digitizing the framework, OEMs and larger manufacturers can transfer a qualified process to suppliers that can then deliver qualified parts.

The U.S. government (through NIST) encourages CCAM’s efforts because they support two national objectives. First, it helps the Department of Defense (and OEMs with U.S.-based operations in general) expand domestic sourcing. Suppliers can add value by delivering qualified parts faster, more accurately and with less time and material waste. Second, because suppliers can be chosen closer to the point of use, it reduces energy use and transportation costs. Both objectives increase the competitiveness of smaller U.S. manufacturers and job shops.

Bakker reports that CCAM is currently working to complete the cell’s architecture, and in 2021 the cell will begin producing test parts. Part of the plan involves intentionally designing imperfections into a part file and, through feedback from the CMM, prove that the cell can resolve issues to automatically create good parts.

“The digital thread enables a collaborative supply chain approach instead of adversarial/piece-price relationship,” notes Waddell. “Government agencies and OEMs need to source parts to companies that have the capability to qualify parts and have standards in place. They know that a lot of small manufacturing facilities don’t have those capabilities, so they support efforts like the ones at CCAM.”

In September 2020, CCAM and Mitutoyo released a white paper titled Open Standards for Flexible Discrete Manufacturing in the Model-Based Enterprise. The paper is available from NIST, and Bakker is one of four authors.